While lead has had many applications in the past, it is phased out almost everywhere due to its

high toxicity to humans. One remaining application is the 12 V starter battery found in almost

every car today. Making the switch from lead-acid to lithium-Ion (Li-Ion) batteries is the basis

of current proposals to update legislation on the topic in the EU.

Lead-Acid vs. Lithium-Ion Battery Cell Technology

Added to those sustainability requirements, Li-Ion batteries also offer superior gravimetric and

volumetric energy density that lead to significant weight and space savings in the vehicle. The

technology also allows to recuperate more energy during braking (higher dynamic charge

acceptance), improving the powertrain efficiency. The lower self-discharging rate, a superior

cycle-stability and extended shelf-life mean that Li-Ion batteries need to be replaced later than

their lead-acid equivalents1. One challenge with Li-Ion technology was the cold

temperature performance that made it unsuitable for cranking the internal combustion engine (ICE)

in cold weather conditions. However, in a recent technology comparison led by the European

Automobile Manufacturers Association EAMA, the Li-Ion cold cranking performance was considered

equal to lead-acid. Although Li-Ion battery prices fell about 89% between 2010 and

20202, cost remains as the main disadvantage.

With the ongoing electrification of the vehicle’s powertrains, the dominance of the cold cranking

requirement is weakened. In the case of plug-in hybrid electric vehicles, carmakers use the

high-voltage system to start the ICE. This means that there is no need for a cold-start capable 12

V system. We believe that lead-acid will be replaced by lithium-ion technology in the 12 V battery

of both hybrid and purely electric vehicles soon, as the extended lifetime is adding true customer

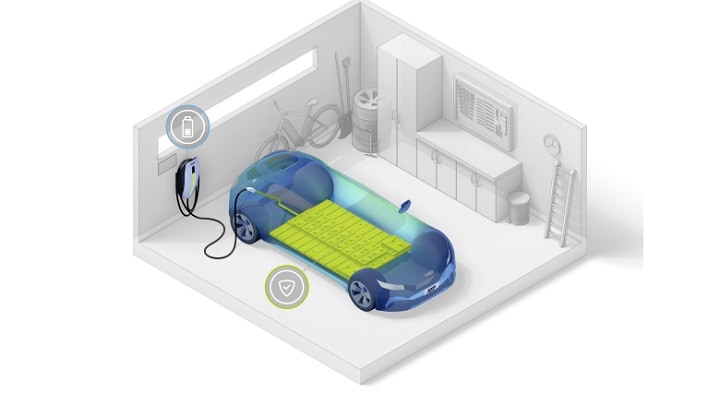

value. Unlike lead-acid batteries, Li-ion batteries require a battery management system (BMS) to

fulfil vital functions including safety, capacity and multi-cell management as well as charging

control.

Benefits of an Integrated BMS Solution

All Li-Ion batteries require a BMS to fulfil vital functions including safety, capacity and

multi-cell management as well as charging control. NXP offers a complete all-in-one solution for

12 V Li-Ion battery management including accurate monitoring and safeguarding of 3 to 6 cell

voltages, temperature sensing and current measurement. The latest C-revision of the battery cell

controller (BCC)

MC33772 comes with

all new features build to answer customers needs. On-chip averaging of measurements effectively

acts as a digital filter and helps to reduce the load on the communication bus and

microcontroller, while allowing for the removal of part of the analog filtering. This helps to

reduce the overall eBOM cost, resulting in a high-quality and cost-optimized solution.

Safety

The AEC-Q100 compliant IC is fully qualified for automotive functional safety applications as it

was designed according to ISO 26262, enabling ASIL C at the chip-level. Similarly, it is suitable

for other lead-acid replacing applications including RV-auxiliary batteries, golf carts and solar

banks as well as in drones, logistics robots and more.

Enablement

As part of our enablement, NXP developed an evaluation board and has several proof-of-concept

boards readily available including documentation, testing and demo software. To complement the

evaluation kit, we will also be offering production ready AUTOSAR® complex device

drivers that accelerate our customers development timeline.

Due to the ever increasing lead regulation as well as the further falling prices for Li-Ion

battery cells the phase-out of automotive lead-acid battery technology might come sooner rather

than later. At NXP, we are ready to enable our customers to switch to smaller, lighter, safer and

longer-lasting Li-ion battery solutions. This is why we offer an integrated and cost-optimized

solution for 12 V batteries in functionally safe automotive and industrial applications. To

facilitate the switch for our customers, we provide a comprehensive evaluation ecosystem and

all-new production ready software building blocks.

Want to learn more about the MC33772C?

Watch our new animation.

References:

-

https://www.acea.auto/files/ES-TECH-TRENDS-V10.pdf

-

https://about.bnef.com/blog/battery-pack-prices-cited-below-100-kwh-for-the-first-time-in-2020-while-market-average-sits-at-137-kwh/