Specifying a power management approach for a given microcontroller and peripherals on an

electronic control unit (ECU) used to be relatively easy. However, with the exponential growth in

automotive system complexity, designers face numerous challenges. They now need devices that are

intuitive, interchangeable and able to facilitate platform development for power management and

safety.

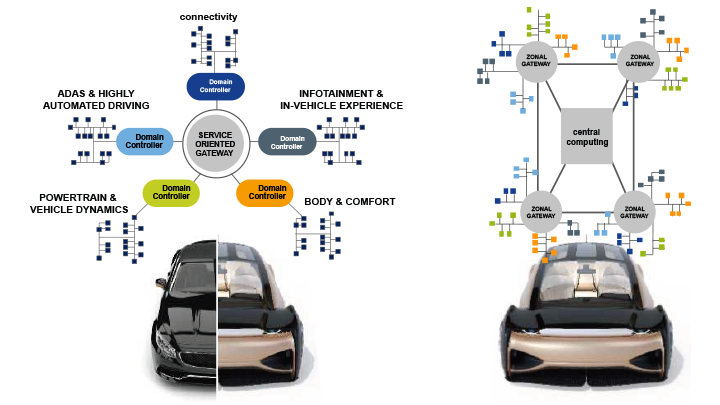

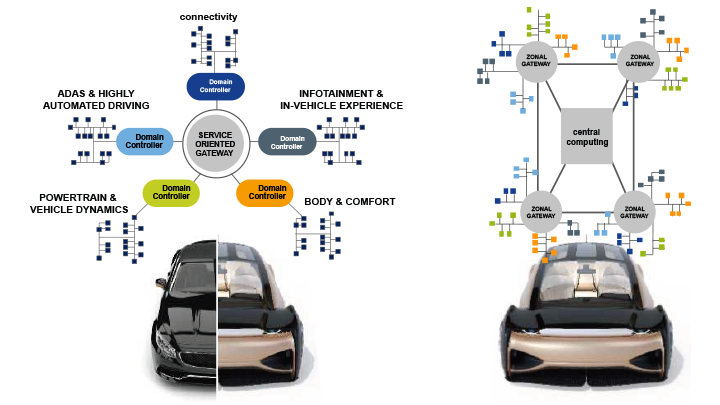

Automotive system complexity continues to rise with the use of high-computing-performance MCUs and

system-on-chips (SoCs) to deliver innovative applications and features, such as electrification,

ADAS and zonal domain controllers. But how do you power all the different processors and system

peripherals or high computing SoCs, safely and efficiently while simultaneously enabling complex

power-up and power-down sequences, simplifying board design, incorporating scalability and

reducing the risk of reliability failures caused by power hotspots. To answer these questions,

let’s analyze some key elements of the power management approach.

Power Management ICs or Discretes

Nowadays, the automotive industry's fast pace means designs are replicated across an entire family

of vehicles with slight variations. Processors are selected first, and then the power management

aspect. A discrete approach offers power scalability and flexibility in the placement and board

layout, but as the solution becomes more complex, other components such as a sequencer, voltage

monitoring and the need of diagnostics are required. Also a small safety MCU with its software to

manage the watchdog and system safety reaction could be required. A power management IC (PMIC) or

a system basis chip (SBC) based solution would support this complete set of features in one device

without compromise on scalability and are easy to design.

SBCs and PMICs for a Power Supply Platform

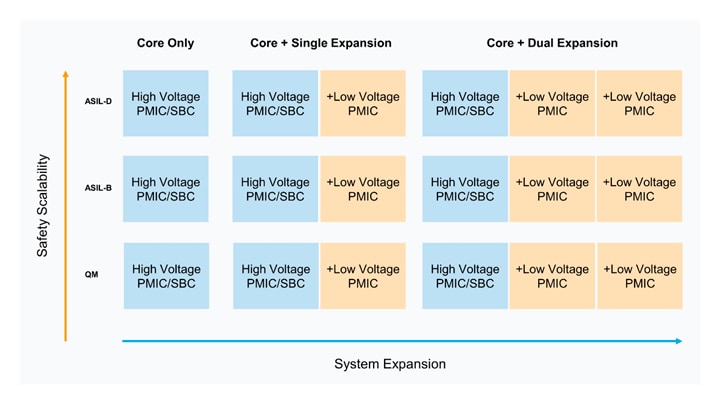

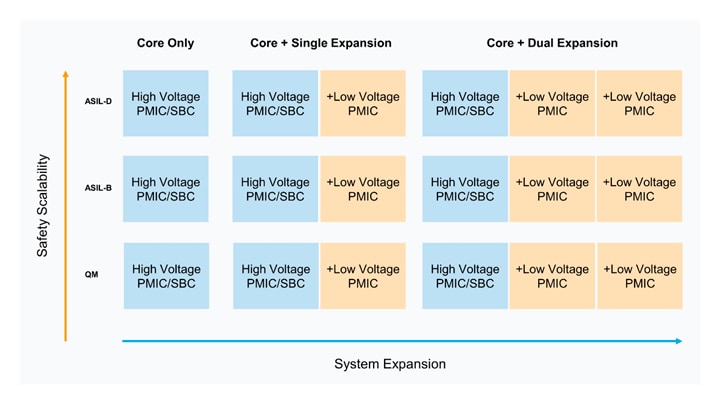

The decision is made to use an SBC IC or a PMIC for the increased complexity in automotive

systems. And due to the different systems, there is the need to transfer power from the battery to

multiple low-voltage domains. Switching to a distributed power architecture solves many of the

design limitations of the 12 V/24 V main battery supply and standard 5 V automotive supply rail.

In a distributed power architecture, high-voltage SBC/PMICs (12/24 V) and multiple low-voltage

PMICs (5 V) can be combined and configured to deliver a range of supply rails for a host of power

needs. Additional rails can be created simply by expanding the number of low-voltage PMICs still

powered by our high-voltage SBC/PMICs.

Functional Safety Across the Board

At NXP, we are well aware about system safety requirements that hardware engineers must satisfy.

That’s why we developed our

BYLink

solution considering a high safety integrity level for our smart safety mechanisms. Our portfolio

is composed of different pin- and-software compatible IC flavour to enable customer platform

approach and to satisfy different safety requirements such as: QM / ASIL B, and ASIL D. With a

multi-PMIC system solution and thanks to the BYLink concept, the safety integration is

facilitated, removing all barriers that such complex safety systems can bring. While individual

low-voltage PMICs can be QM or ASIL B rated, the whole power domain ECU can gain ASIL D level

through the primary high-voltage PMIC since it is responsible to monitor the critical voltages and

the safety MCU, plus transition the system into safe state in case of system failure.

Synchronized Sequencing

Another challenge of system complexity is the synchronization of the power-up and power-down

sequence needed to initialize different controllers and peripherals. A programmable power up/down

sequencer embedded in each device which can be configured to fine-tune the sequence time is an

ideal option for flexibility and minimizing as well system BOM.

How should devices be synchronized in a distributed architecture?

NXP’s new BYLink concept helps ensure the synchronization between all devices to avoid any

external additional components. This reliable and cost effective solution allows for individual

devices to be physically separated, reducing major heat spots since thermal management is at ECU

level.

NXP’s Safe, Scalable, Expandable BYLink System Power Platform Is the Answer

Enabling scalable power rails in a common IC footprint, which also share a familiar configuration

interface for software portability between devices. These power management building blocks provide

design flexibility and scalability with cascaded system PMICs essentially behaving as a single

power supply solution. With the new BYLink platform we are able to offer an easy and vital link

towards a safe and configurable power management design.

To learn more about the BYLink platform, read the

whitepaper.