- Smarter World Blog

- Reimagining CAN for Industrial

Reimagining CAN for Industrial

Controller area network (CAN) is a highly relevant communication technology for automotive and industrial applications. As additional functionality is integrated into these applications, demand for more complex networks and faster data rates is increasing. Both needs collide with the resulting increased effects of signal ringing on the bus lines, underlining the limited ability of the CAN medium access legacy technology. The introduction of CAN signal improvement capability (SIC) may just change that.

Decades of CAN Transformation

CAN was introduced in the 1990s with a focus on the automotive industry. The technology has grown since then to support more complex vehicle networks and an increasing number of nodes. CAN flexible data rate (FD) was developed to meet the increased demand for higher bandwidth communication on the CAN network.

CAN FD is an extension of Classical CAN, which enhances the exchange of data up to 5 Mbit/s by using high-speed (HS) CAN transceivers. But its achievable data rate is not likely to exceed 2 Mbit/s in real topologies because of the effects of signal ringing. CAN SIC transceivers such as the NXP TJA146x actively improve the signal and thus are less limited by ringing, achieving higher bit rates in more complex topologies, complementing existing CAN FD networks.

| CAN Transceivers | Maximum achievable data rate |

|---|---|

| CLASSICAL CAN | Up to 1 Mbit/s |

| CAN FD | Up to 5 Mbit/s |

| CAN SIC | Up to 8 Mbit/s |

We discussed the benefits CAN SIC brings to automotive in one of our previous blogs, but those benefits are not only confined to automotive.

Shifting Gears to Industrial

The success of CAN SIC in automotive has led to its adoption for industrial applications. Although IP communication is gaining more traction, CAN remains a key technology in industrial because it is robust, reliable and cost competitive.

CAN networks are already present in several industrial segments including embedded machine control, mobile robotics, healthcare, elevators, on the ocean ground and even in outer space. With CAN SIC transceivers, it’s easier to significantly improve the performance of CAN FD networks in these industries. That improvement is crucial because some industrial applications need to span long distances in complex topologies to connect their networks. If unattended, this could lead to signal ringing, making it more difficult to reach desired bandwidths or create an efficient network design in terms of cabling and cost.

Achieving More with CAN SIC

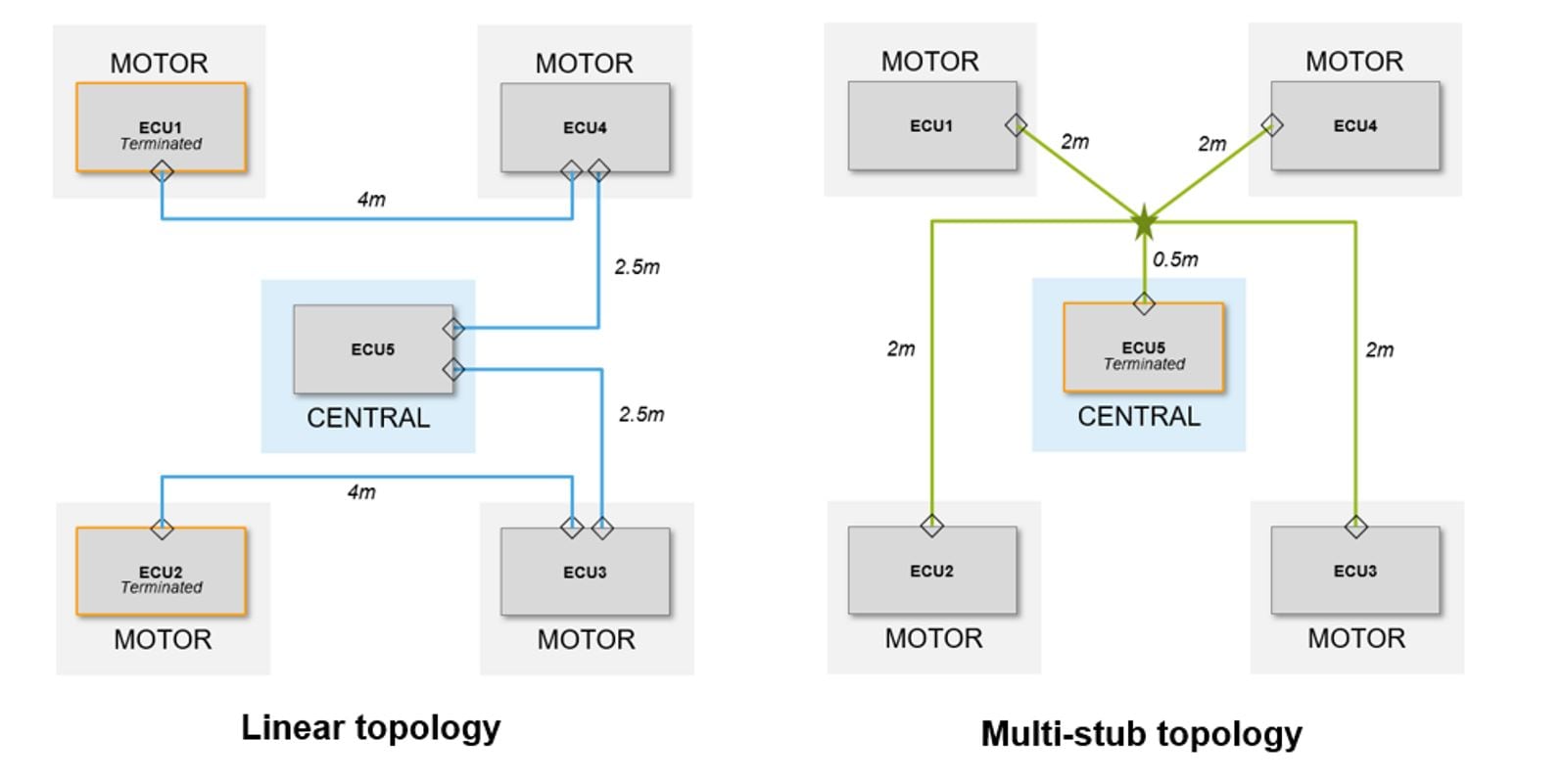

To illustrate the benefits of CAN SIC, we examined the case of mobile robotics. This type of applications can be implemented in a daisy chain network, usually with a limited achievable data rate of 2 Mbit/s to avoid the limitations of the signal ringing and to run the network reliably. But there is an alternative topology that offers multiple benefits.

The multi-stub topology, with central termination, involves the optimization of cable length, resulting in decreased weight and cost for both the primary and potentially redundant network. It also reduces the risk of communication and termination loss and provides standardized motor electronic control units (ECUs) by migrating the termination to the central ECU. Despite these benefits, a major shortcoming of the topology is that the stubs increase the effects of signal ringing and consequently limit the data rates achievable with standard CAN FD transceivers.

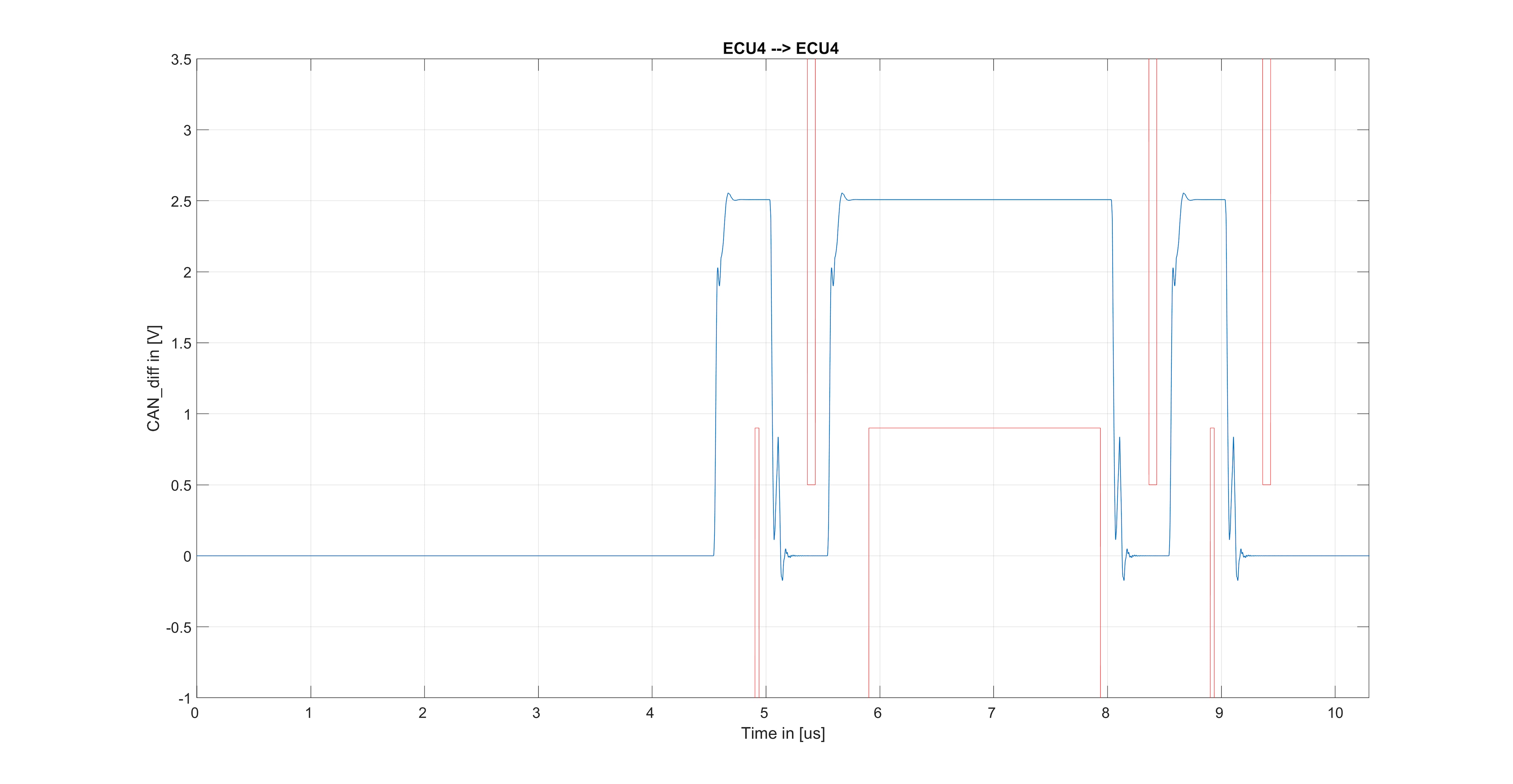

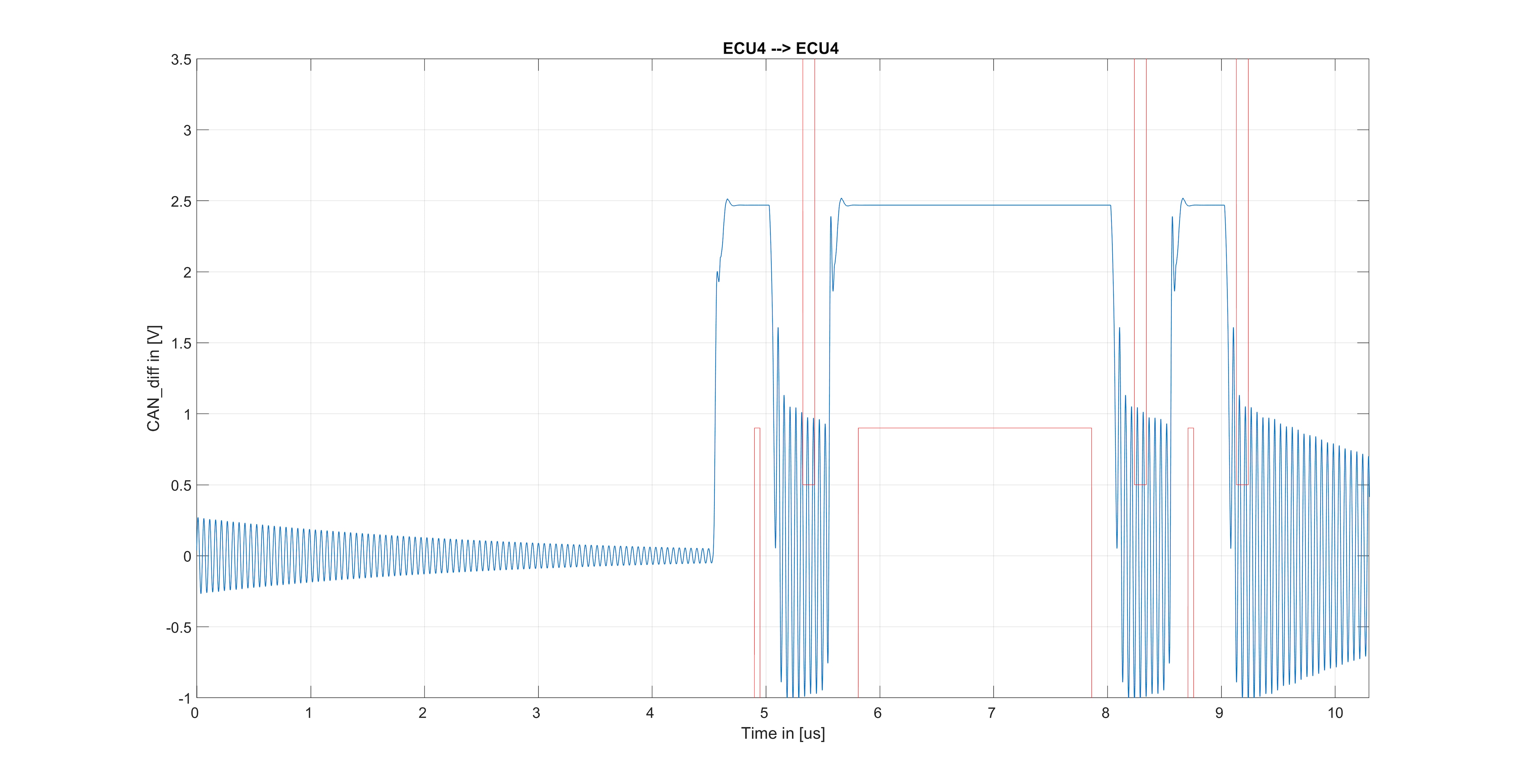

By actively improving the signal, CAN SIC can circumvent the effects of ringing. The simulation results in Figure 2 shows how CAN SIC enables reliable communication versus CAN FD in the multi-stub topology, allowing an increase in the data rate beyond 2 Mbit/s and creating a more efficient and safer topology design. Without CAN SIC, the more efficient topology would not be able to run reliable 2Mbit/s CAN FD communication.

Simulation of CAN SIC (Figure 2) and CAN FD (Figure 3) performance at 2 Mbit/s in the same multi-stub topology with central termination, as featured in Figure 1. The red boxes indicate the no-go area for the signal for reliable communication, the red boxes for CAN SIC are tighter due to improved symmetry timing performance. By implementing CAN SIC, signal is improved, creating room to increase achievable data rate up to 5 Mbit/s.

Discover our CAN portfolio and learn more about our CAN SIC offerings.

Looking Ahead

There is still some evaluation needed regarding long networks and CAN SIC. Within CAN in Automation (CiA), the nonprofit users’ and manufacturers’ group established in 1992, the marine industry is looking for CAN FD networks with a length of about 500 m. There are also other application domains that have long network demands, including cranes, earth-moving machinery and elevators, just to name a few. A key focus across these domains is suppressing ringing on network lines while preventing voltage drops from causing bit errors.

“Industries such as construction and mining machines, as well as maritime electronics and rolling stock are sometimes conservative in adopting new communication technologies,” explains Holger Zeltwanger, CiA Managing Director. “In collaboration with interested CiA members, we are evaluating the use of NXP’s TJA146x CAN SIC transceivers in long networks with a combination of long and non-terminated stubs. Such evaluation will enhance the acceptance of CAN SIC in non-automotive applications as increased demand for functional safety and cybersecurity continues to drive the transition from Classical CAN to CAN FD.”

Authors

Teun Hulman

Teun Hulman is Product Marketing Manager within Product Line In-Vehicle Networking (IVN), where he has global responsibility for the CAN SIC portfolio. Previous to joining the marketing team he worked at the In-Vehicle Networking R&D department on the development of CAN transceivers. Teun holds a Master of Science degree in Electrical Engineering.

Holger Zeltwanger

Holger Zeltwanger initiated the CAN in Automation (CiA) users’ and manufacturers’ group in 1992. He is the Managing Director of the CiA since the beginning and also an active member of multiple standardization groups for in-vehicle networking and network applications.