We are well into the era of Industry 4.0 with more and more technologies being

adopted for industrial automation. Some newer technologies are enabling AI and

machine learning, data analytics, industrial networking, cyber security and

functional safety. However, the bulk of industrial automation that sits in the

middle of all the other technologies still relies on robot and motion control.

From time to time, motion control is mentioned with motor control and there is

some confusion about these two terms. What is the difference between these two

concepts and how do we apply the right solution to either or both of them in

industrial automation? Read on for a summary of the differences between motion

control and motor control and how to make them work together.

What Is Motion Control?

Motion control is a sub-system of an industry automation system. It

synchronizes and controls multiple motors to complete a sequence of movements.

For example, a multi-axis robotic arm requires a number of motors to operate

together seamlessly to make a specific move.

Motion control

is used mainly for trajectory planning, speed planning, interpolation

algorithm and kinematics conversion. Motion control systems are often seen in

printing, packaging and assembly applications.

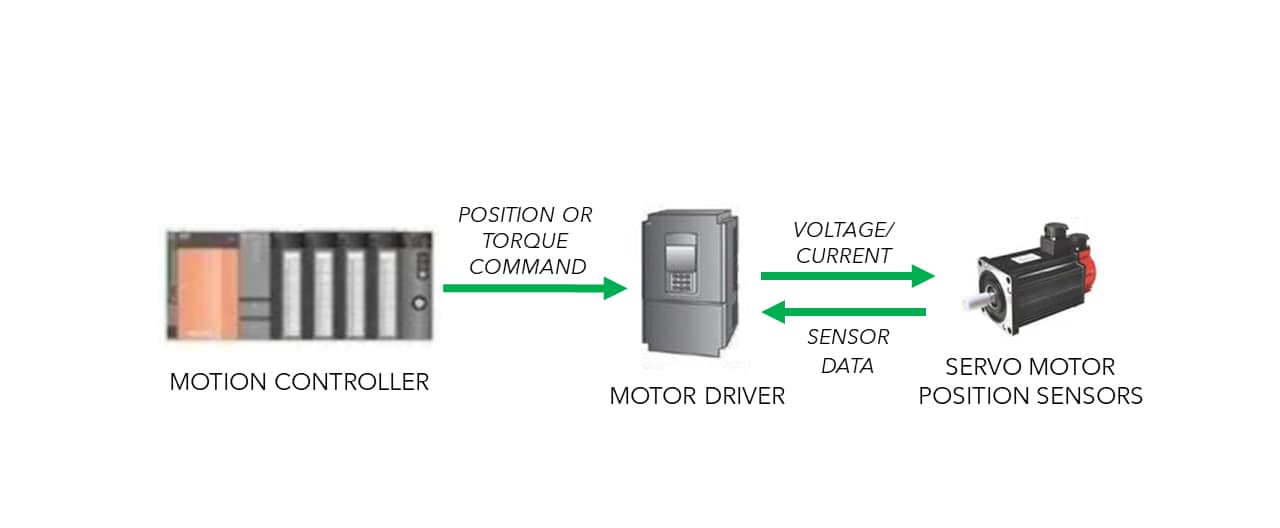

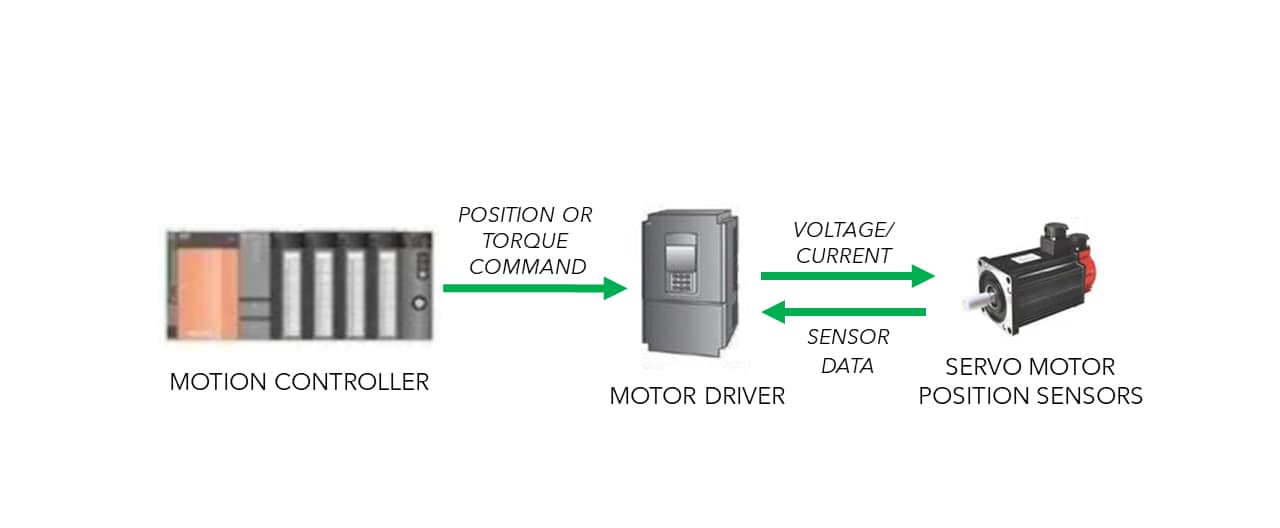

As shown below, a motion control system typically consists of these major

components:

-

A motion controller that generates trajectory planning and then provides

control commands to motor drivers

-

Motor drivers that convert the control commands from the motion controller

(usually a speed or torque signal) into a higher power voltage or current

signal to drive the motors

- Motors that execute movement according to control commands

-

Position sensors that provide the position/speed data of the motor rotor to

the position/speed controller to achieve the precision position/speed

control

The function of the motion controller in system is to synchronize and

control multiple motors to complete a sequence of movements.

The function of the motion controller in system is to synchronize and

control multiple motors to complete a sequence of movements.

Designing for next-generation smart, connected and secure industrial

drives just got easier.

Get more insight by reading another insightful

blog.

Motor Control vs. Motion Control

Motor control, on the other hand, is a system or a technique that is more dedicated to

controlling the spinning of the motor. A typical motor control system adjusts

one or more of the parameters of the torque, speed and position of an

individual motor to reach the target values. Depending on the type of the

motor, the requirements and techniques to drive it can vary greatly. A motor

controller usually has no planning ability—the advanced drivers have simple

position and speed planning abilities. Therefore, a simple way to explain the

difference between motor control and motion control is:

-

Motor control is a part of the motion control system (usually a current

loop, working in torque control mode)

-

However, sometimes it can be confusing because the position loop/speed

loop/torque loop of motor control can be implemented either in the motor

controller or in the motion controller.

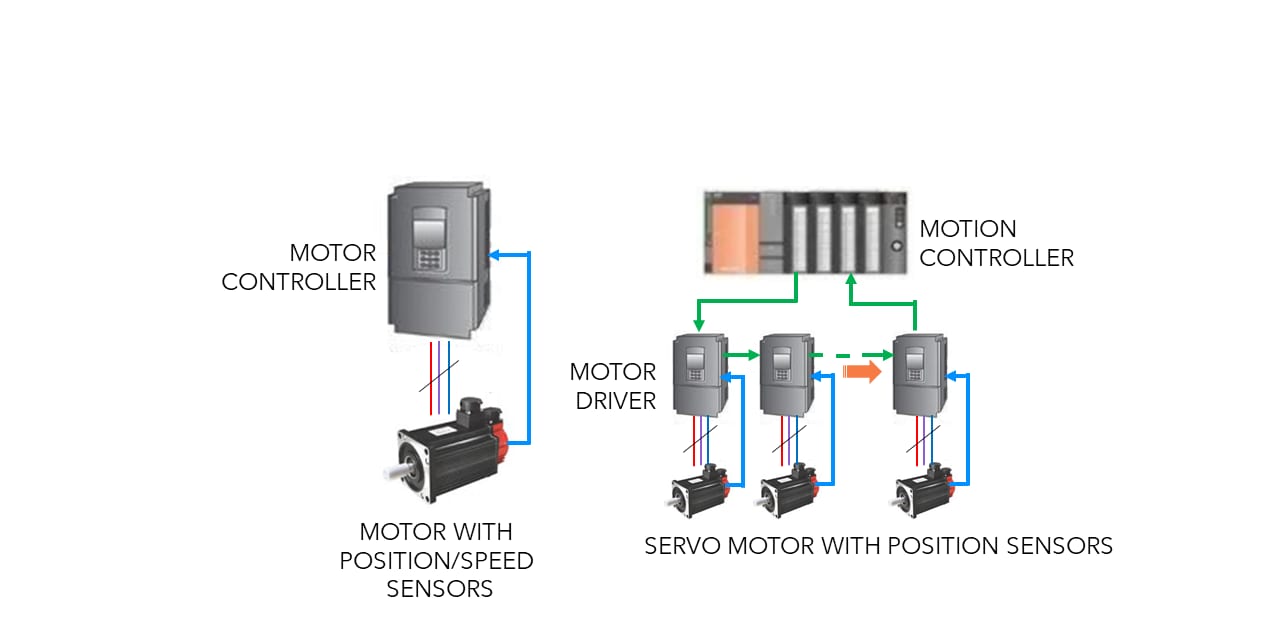

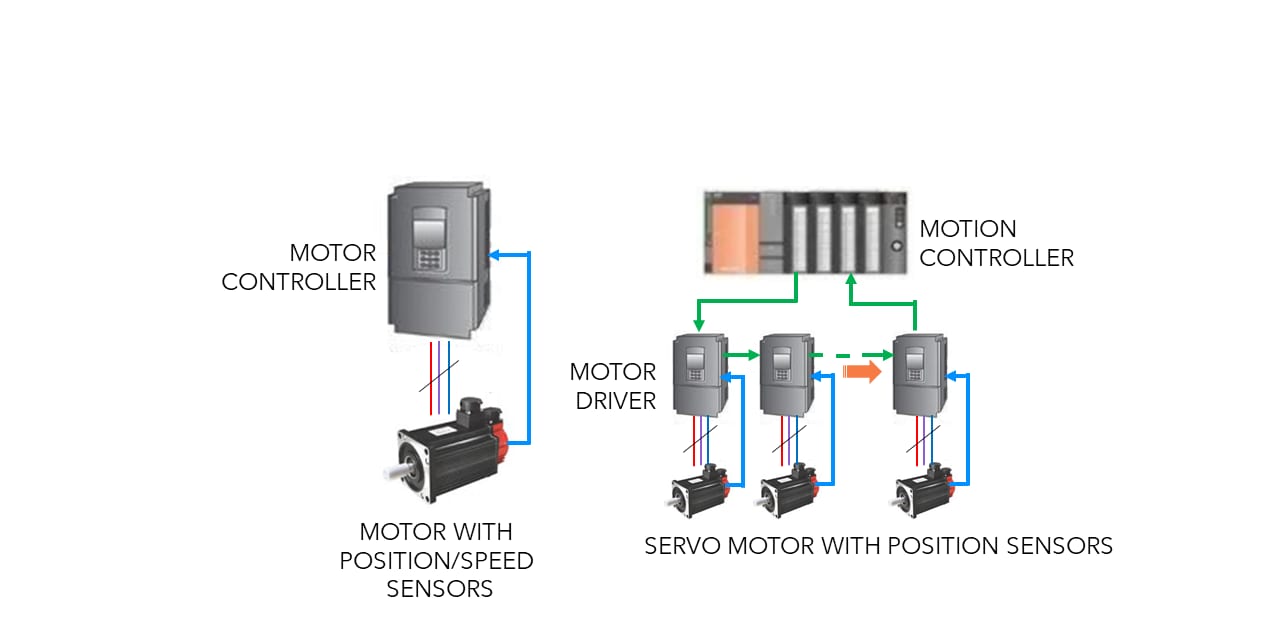

The interaction between motion controllers and motor controllers in a

system.

The interaction between motion controllers and motor controllers in a

system.

Now that we know the differences between the two systems, it becomes clear

that the design requirements or resources for them are quite different as

well.

Motor control is highly focused on making the motor spin properly, or rather,

focused on communication. In order to do that, the motor controller needs to

interface with a variety of sensors, process both analog and digital signals,

as well as generate waveforms to drive the motor. These all happen in a very

short loop of time that can range from 50us to 300us.

NXP offers the silicon to enable secure, connected and high-efficiency

motor control for industrial applications.

Motion control, however, often acts as a system supervisor that requires

communication in between multiple motor controllers, other sources such as

data via Ethernet (EtherCAT and TSN.), CAN, RS485 and commands from a

human-machine interface (HMI) panel. As mentioned, a motion controller may

also take part in some of the motor control tasks such as controlling the

speed loop, the position loop or even the torque loop. Therefore, the

real-time control loop of a motion controller can vary from 100us all the way

to hundreds of milliseconds, depending on what actual tasks the motion

controller is taking part in.

Designing a Motion Control System

A motion control system can be a fairly complex design that covers a lot of

aspects such as motor control, industrial networking, HMI, encoder/decoder,

security and safety. Thus, it requires multiple control units to coordinate

with each other in the system.

This is where you need a full suite of devices for the motion control

designers to choose from—and that’s where NXP and its wide portfolio of

microcontrollers (MCU) and microprocessors (MPU) comes in.

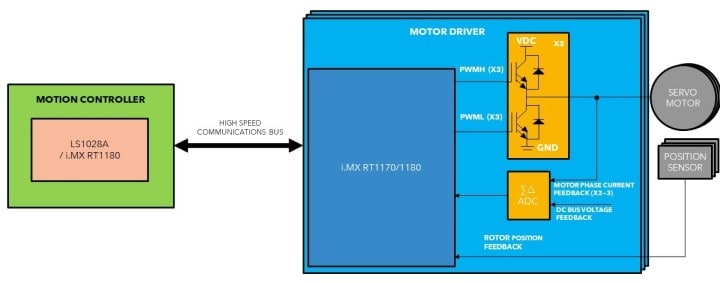

For the motor controller, NXP’s

Kinetis V MCUs,

Kinetis E MCUs,

LPC MCUs

and

digital signal controllers (DSCs)

offer options from controlling a simple motor with an Arm®

Cortex®-M0+ core, to running FOC algorithms on dual motors with

a Cortex-M33 core or a highly efficient DSC core. With the popular flashless

i.MX RT crossover MCUs, more motors can be controlled precisely at the same

time. Not only do these MCUs have a wide range of processing capabilities to

choose from, they are also integrated with the peripherals that are

well-suited for motor control, such as high-speed and high-resolution ADCs,

high-speed comparators, flexible motor control timers and PWMs and DSP

accelerator. Safety features such as fault detection and auto-shutdown can

work together seamlessly with the industrial safety compliances offered by

these devices.

What’s the best MCU for your motor control design?

Explore our comprehensive

motor control guide

for the latest solutions.

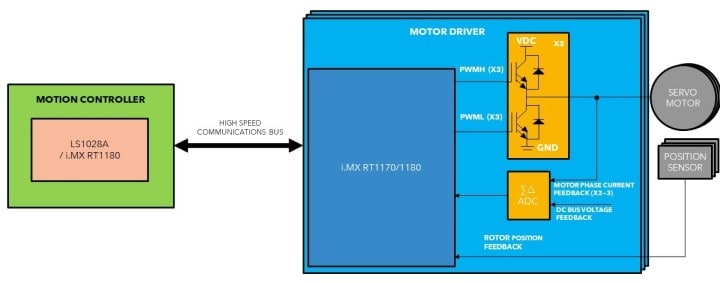

For the motion controller, NXP offers both the

i.MX RT crossover MCUs

and the MPU product lines, including the

Layerscape

and the

i.MX series processors. Those devices support a rich integration of industrial communication

interfaces such as Ethernet/IP, Profinet, EtherCAT and TSN. The multiple-core

architecture generates enough horsepower for communication protocols, motion

profile planning and real-time loops control. They are also equipped with

advanced timers to support the multiple modes counting and flexible pulse

train outputs.

A motion control system can use a wide range of MCUs and MPUs to enable

multiple motor drivers that facilitate synchronized movements across a

single robotic arm, for example.

A motion control system can use a wide range of MCUs and MPUs to enable

multiple motor drivers that facilitate synchronized movements across a

single robotic arm, for example.

To accelerate the time to market of the motion control system, a quick and

easy way for proof-of-concept and prototyping is keen. Therefore, NXP has been

developing reference design platforms that provide rich features in industrial

motion control and meet industrial automation standards. We recently announced

the

i.MX RT industrial drive development platform, which is based on the i.MX RT crossover MCU and features multi-motor

control, deterministic communications and a foundation for IEC 62443 security

compliance. Available today, the

quad motor control development platform

implements a full set of NXP products including the i.MX RT crossover MCU and

EdgeLock® SE050 secure element. These devices work together to demonstrate the features needed for an

industrial motor control system, such as power management, driving four

motors, industrial communication interfaces, HMI touch panel interface and

security integration.

In summary, we have covered the definition of motion control, the difference

between motor control and motion control, as well as the trends in the

industry for motion control system design requirements. Keep following NXP for

more

motor control solutions.