Tens of billions of RAIN RFID tags are used each year to identify and track items as they move through the various stages of life within a value chain. In most cases, a small amount of memory is all that’s needed to store product and tag IDs, making it possible to distinguish one item from another and report item location and/or status within the system.

So why, then, do some RAIN RFID tags offer a little bit of extra memory? Because there are some situations – especially in supply chains and the industrial Internet of Things (IoT) – where even a little bit of additional memory can make a big difference. The extra information that an extended-memory tag can store, beyond the product and tag ID, can help increase efficiency, add automation and reduce operational costs.

What are Extended-Memory Tags?

RAIN RFID tags that offer extended memory are essentially the same as other RAIN RFID tags – they follow the same protocols and are fully interoperable with the broader RAIN RFID ecosystem – but they include optional memory resources not found in basic tags.

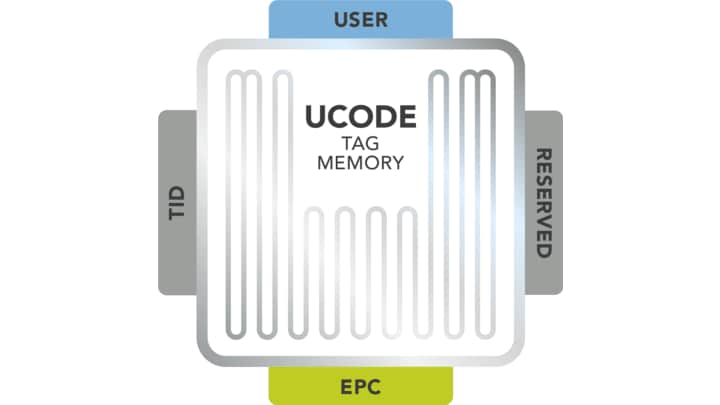

UCODE Tag Memory Banks

UCODE Tag Memory Banks

All RAIN RFID tags use the GS1 UHF Gen2 protocol. According to this protocol, the standard memory in a RAIN RFID tag is divided into four banks:

- Reserved Memory, which stores passwords used to lock and unlock access to the tag’s other memory banks. It also provides the ability to “kill” the tag, so it doesn’t respond to a reader.

- Tag Identifier (TID) Memory, which stores the TID, a unique number assigned to the tag during manufacturing.

- Electronic Product Code (EPC)/Unique Item Identifier (UII) Memory, which stores the EPC or UII assigned to the item associated with the tag.

- User Memory, which stores any extra data that might be required by the system, beyond the EPC/UII information.

The first two banks of tag memory, Reserved Memory and TID Memory, are essentially fixed in size, but the EPC Memory and the User Memory can vary. Most tags offer the minimum amount of memory required for EPC storage (96 or 128 bits), and have little or no User Memory. Extended-memory tags, on the other hand, offer larger EPC memories (up to 496 bits), and give the option to store many hundreds of bits in User Memory.

Extended Memory for Extended Options

Having extra memory to work with opens up a number of opportunities. Tags can store larger EPC identifiers as well as relevant information over and above the basic identifier, such as manufacturing status, model information or value-chain data.

Also, essential details, such as unit-of-use serial numbers, country of origin or the concentration of a specific chemical, can be recorded as the information becomes available, as can lot numbers, expiration dates, compound dates or beyond-use dates. This can be very important when products are moving between different value-chain partners running systems that don’t talk to each other. Data needs to be transferred, but doing so may not be possible without complex security arrangements and connectivity. Storing important data on the tag itself, along with the product or item ID, means downstream partners get the right data at the right time.

As an added bonus, data stored in extended memory can be accessed at any time, even when a cloud connection isn’t available, so tagged items can still provide all their information to a reader, including data stored in extended memory, wherever they are.

Here’s a look at some industry-specific benefits offered by the extended memory:

Manufacturing Operations

On the production line, extended-memory tags can help monitor the progress of complex products from start to finish, and can record status and part IDs during assembly. In aviation and automotive, details about product assemblies can be recorded during work-in-progress, for full traceability right from the birth of the product without the need to rely on system connectivity.

Inventory Management

Tagging items and containers with more detailed product information supports digital kanban operations, and using memory to store date, batch or part-generation information helps ensure that the right part is available at the correct line-side location for just in sequence operations.

Automated Tool Management

On the factory floor, extended memory supports automated tool management and automatic tool checkout, thereby increasing tool availability, personnel accountability and accuracy of tool-maintenance schedules.

Supply-Chain Management

Logistics gets a boost, and just-in-time supply chains operate more smoothly, when tagged parts and containers can provide automatic proof of dispatch, date information from suppliers and issue automated receipts.

Airline Baggage Tracking

The latest formats for baggage tracking use high-performance tags, some with additional tag memory, to store extra information about the bag, its destination and its owner, so fewer bags are misplaced during transfer and bags are loaded on the right plane in time for wheels up.

Perishables and Pharmaceuticals

In many industries, understanding a product’s expiration date is critical for safety. Extended memory is often used to store time/date and batch information, which then stays with the item as it travels through manufacturing and the supply chain. Stored data can be checked at any point in the product’s life cycle, even in places where there’s no network connectivity.

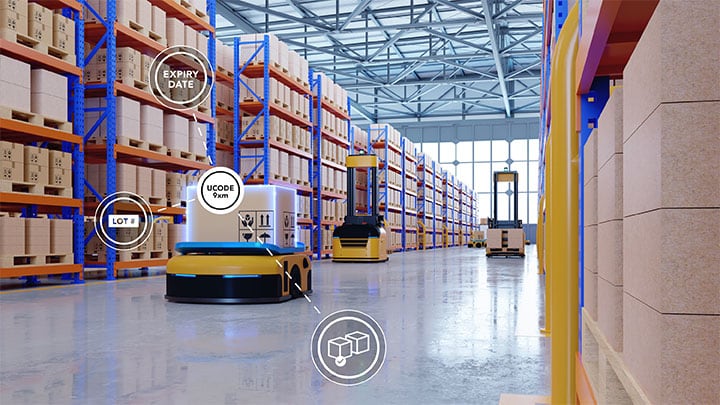

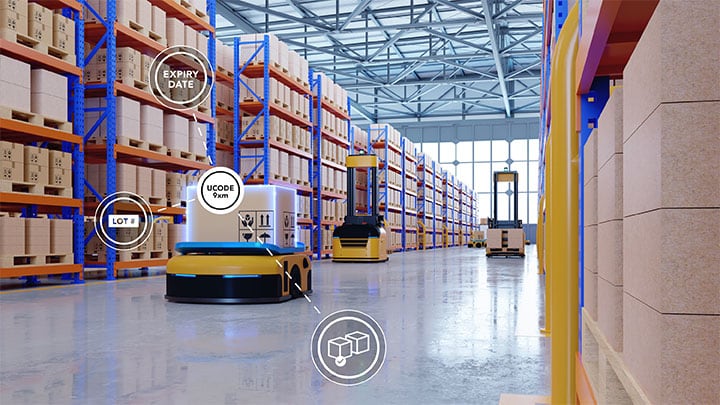

UCODE 9xm enables tagging items and containers with more detailed product information

UCODE 9xm enables tagging items and containers with more detailed product information

The NXP Approach to Extended-Memory Tags

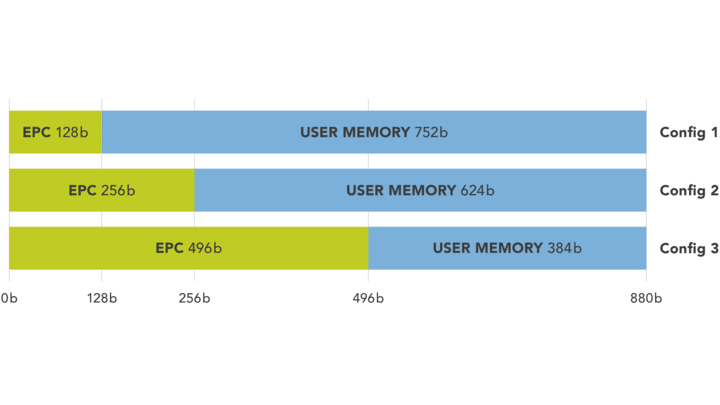

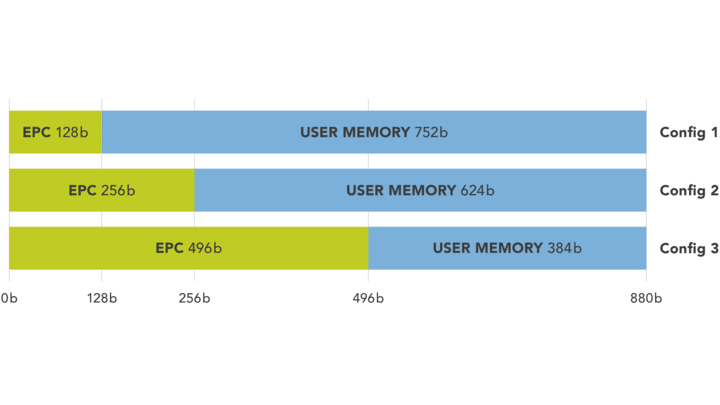

At NXP, we recommend our customers use the UCODE 9xm extended-memory IC when they want additional memory. UCODE 9xm offers the same extensive feature set and exceptionally high RF performance as the very successful UCODE 9, but with three flexible memory configurations that offer up to 496 bits of EPC/UII Memory and up to 752 bits of User Memory.

UCODE 9xm offers extended memory for extended options. Explore the extensive feature set and benefits by watching the on-demand webinar:

Introducing UCODE 9xm.

As shown in the diagram, the combined total of 880 bits of memory space is shared between the EPC/UII and User Memory, making it easy to balance the requirements based on the individual use case. In a manufacturing application, for example, the entire 752 bits of User Memory might be used to store details about the product, while an automotive or airline application might use the full 496 bits of EPC/UII Memory to conform to relevant data standards. Either way, the memory configuration is programmed in during the tag-encoding process by the customer, which means a single IC can be used to fulfill a number of use cases helping to lower stock keeping unit (SKU) complexity and providing the customer configurable flexibility necessary for some of today’s complex value chain environments.

Customer configurable UCODE 9xm Memory

Customer configurable UCODE 9xm Memory

Learn More

By storing extra information beyond basic EPC/UII identification, extended-memory UCODE tags can be used to solve some of today’s most pressing IoT and supply-chain challenges. Learn more about how NXP uses the UCODE 9xm to address these challenges.