- Smarter World Blog

- How EV Developers Get Ahead of the Curve for High-Voltage Battery Management Systems

How EV Developers Get Ahead of the Curve for High-Voltage Battery Management Systems

Global sales of electric vehicles continue to grow, with a total of 10.5 million new BEVs and PHEVs delivered during 2022, an increase of 55% compared to 2021. Massive investment by carmakers to optimize technologies, with most gains from improvements in the battery chemistry and in the performance of the battery management system (BMS), means that the average battery range is now treble to what it was a decade ago. Consumers are now more confident about buying BEVs with quoted ranges of 300 miles and more.

Though most BEVs on the roads today run on 400 V, there is a gradual shift to 800 V battery architectures. By the middle of the decade, more and more carmakers anticipate they will have 800 V models in their offering. Running on such a high voltage gives these BEVs much lower charging times, making them even more attractive to potential buyers.

Although high-voltage BMS (HVBMS) architectures exist, there is no blueprint for them – it’s not like the old days when the same internal combustion engine (ICE) could, with a few mechanical and electronic tweaks, fulfill the powertrain needs of a range of models. The market is evolving from a new vehicle model every 6-8 years to more frequent updates or upgrades, similar to the smartphone market with yearly innovation spins. During this transition period, architectures are highly variable, and there is no standard way of doing it. The challenge for OEMs and Tier 1s is to bring the latest semiconductor innovations into the market as soon as possible. Indeed it’s not just the semiconductor innovations that are required; the functional safety of these devices needs a lot of attention and design effort.

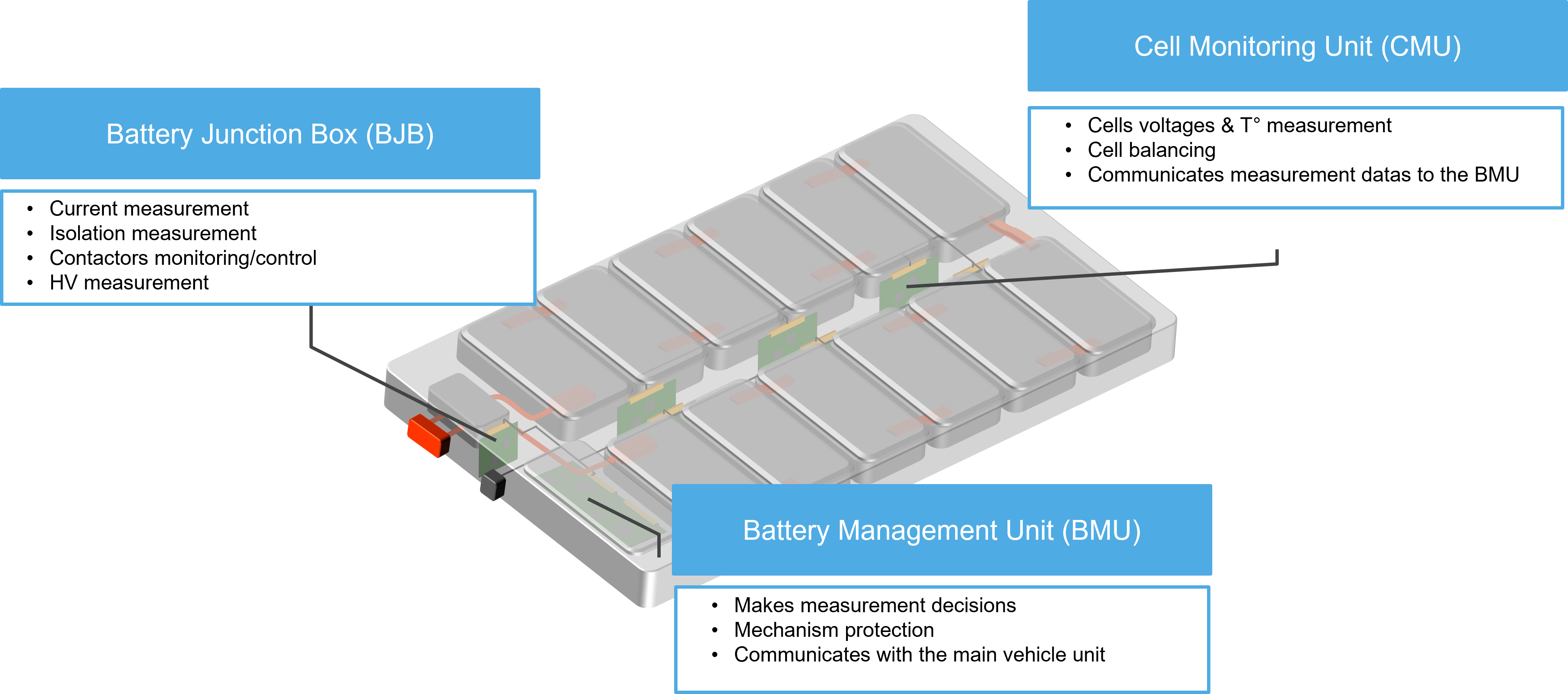

As there’s no ‘one-glove-fits-all’ HVBMS architecture, any reference design must be flexible enough to adapt to all possible upcoming architectures. They need to address the varying system voltages from 400 V to 1000+ V, as well as upcoming hybrid 2 x 400 V configurations for switchable 800 V charging and 400 V driving. System architects need to assess how to set up the BMS internal communication between the battery management unit (BMU), which is the brain of the system and the cell monitoring unit (CMU) and the battery junction box (BJB) subsystem PCBAs. Considering next-generation function aggregation architectures, for example, via a propulsion domain controller, CAN FD poses an interesting alternative to state-of-the-art isolated daisy chain buses, by allowing the removal of the controller from the battery pack.

With the development of the high voltage battery management system reference design (HVBMS-RD), NXP showcases system-level knowledge and exceptional functional safety expertise. In addition to the scalable and flexible hardware architecture, the HVBMS-RD comes with an extensive range of supporting documentation that enables accelerated time-to-market and reduces the development effort and associated risk. The solution combines all the latest BMS silicon with production-grade software device drivers and reusable functional safety documentation, delivering ASIL D measurement values the customer’s application layer software can trust.

Find more information about NXP's new HVBMS-RD and read out latest whitepaper entitled ‘NXP HVBMS Reference Design Helps Developers Get Ahead of the Curve’.

Authors

Emiliano Mediavilla Pons

Emiliano Mediavilla Pons joined NXP in 2015 as Product definer and functional safety architect for Solid State Lighting business, coming from the Tier1 automotive sector. From 2018, Emiliano joined the BMS group as Principal Functional Safety Architect in the application team. For the last fourteen years, Emiliano has been working on the automotive sector as system, product and functional safety architect. Emiliano holds a Bachelor’s degree in Electronics Engineering from University of Oviedo, a Master’s degree in Automotive Electrical and Electronics from Polytechnic University of Catalunya and a Master’s degree in Business Administration (MBA) from University of Oviedo.

Konrad Lorentz

Konrad Lorentz holds a Bachelor’s Degree in International Project Engineering from Reutlingen University. He joined NXP through a thesis paper on the Automotive Value Chain in 2020 and now holds a position as Product Manager in the BMS Marketing Team.