Functional Safety is key to ensure that products operate safely — and

even if they fail, they are still capable of entering in a controlled safe

operation mode. Let’s say you want to make a left turn using your

electrical power steering and the control unit malfunctions. With Functional

safety and enough redundancies, the car will give you degraded assistance in

the steering to move it in a safe place.

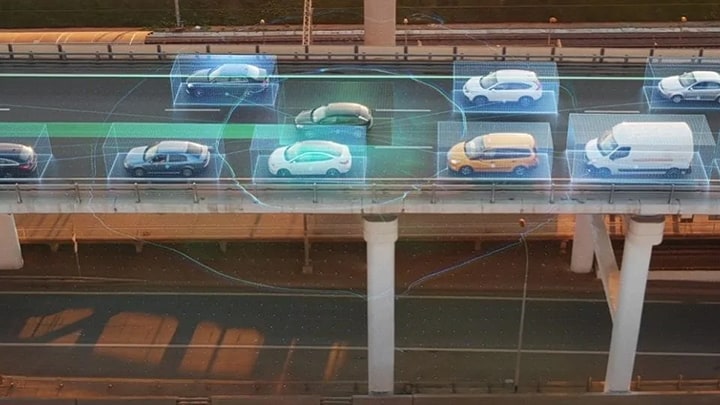

Think about the modern car. It’s more complex than ever, with

increasing electronics and millions of lines of code running it. As our

car becomes more automated, the complexity will continue to rise.

It makes functional safety even more important to automakers. They

can’t choose to ignore it.

Today, vehicles operate with a traditional fail-safe engine control unit

architecture. This detects the fault, transitions the system to safe state but

at the end, the driver is still able to take back the control of the vehicle.

Gradually, as electronic systems evolve to Levels 4 and 5, the dependence on

the driver diminishes as the vehicle has sufficient redundancy and diversity

to continue full operation despite the detection of a fault.

System failure prevention: from fail-safe system architectures

In a fail-safe architecture, the power supply delivers and monitors over- and

under-voltage to the microcontroller and the other peripherals. It is also in

charge of sensing and evaluating the MCU safety operation through the watchdog

and HW Error monitoring functions. If a fault is detected, the system goes

into safe state (driven by the safety power supply) which guarantees that the

function is maintained in a known and defined state (not uncontrolled).

To fail-operational system architectures: How do they work?

As vehicles move beyond the first levels of automation, new fail-operational

system architectures are required to add more functionality to the vehicle.

Fail-operational systems guarantee the full or degraded operation of a

function even if a failure occurs. In this instance, the target applications

are characterized as needing high-performance, a high level of safety

integrity and a high level of availability. The fault detection and reaction

is controlled by independent hardware since a fail-operational system includes

minimum two fail-silent units. To remove common cause failures, even the

supply is ensured by redundant and independent batteries (VBAT1 and VBAT2).

Depending on the SAE level targeted by the car maker, the backup function can

be used for several seconds, to several minutes. For Level 3 of automation,

the driver is informed by the system that there is a failure and to take back

the control of the vehicle. Starting at L4, the driver is no more informed of

a fault, so the robot (car) will most likely park the vehicle in a safe area

for the occupants of the vehicle and the other road users. As such, NXP is

capable of providing functional safety systems that are more and more advanced

and therefore more reliable and effective than ever before. Safety

architectures and system design aim to enable full redundancy to facilitate

higher levels of autonomous driving and fault tolerance in the case of

failure.

Depending on the SAE level targeted by the car maker, the backup function can

be used for several seconds, to several minutes. For Level 3 of automation,

the driver is informed by the system that there is a failure and to take back

the control of the vehicle. Starting at L4, the driver is no more informed of

a fault, so the robot (car) will most likely park the vehicle in a safe area

for the occupants of the vehicle and the other road users. As such, NXP is

capable of providing functional safety systems that are more and more advanced

and therefore more reliable and effective than ever before. Safety

architectures and system design aim to enable full redundancy to facilitate

higher levels of autonomous driving and fault tolerance in the case of

failure.

Depending on the SAE level targeted by the car maker, the backup function can

be used for several seconds, to several minutes. For Level 3 of automation,

the driver is informed by the system that there is a failure and to take back

the control of the vehicle. Starting at L4, the driver is no more informed of

a fault, so the robot (car) will most likely park the vehicle in a safe area

for the occupants of the vehicle and the other road users. As such, NXP is

capable of providing functional safety systems that are more and more advanced

and therefore more reliable and effective than ever before. Safety

architectures and system design aim to enable full redundancy to facilitate

higher levels of autonomous driving and fault tolerance in the case of

failure.

Depending on the SAE level targeted by the car maker, the backup function can

be used for several seconds, to several minutes. For Level 3 of automation,

the driver is informed by the system that there is a failure and to take back

the control of the vehicle. Starting at L4, the driver is no more informed of

a fault, so the robot (car) will most likely park the vehicle in a safe area

for the occupants of the vehicle and the other road users. As such, NXP is

capable of providing functional safety systems that are more and more advanced

and therefore more reliable and effective than ever before. Safety

architectures and system design aim to enable full redundancy to facilitate

higher levels of autonomous driving and fault tolerance in the case of

failure.